ENGINEERING BENEFITS

Victaulic Grooved Couplings Applied Engineering Benefits

Accommodating Seismic Movement

it can be done with grooved technology and here is how and why you want to use it.

The main approach to piping a building to accommodate seismic activity is to use a rigid piping system that will minimize overall piping movement. Typically, more than 95 percent of the grooved couplings used in a piping system will be rigid, while the remainder will be flexible couplings. Why is that important? Because too much swing could affect other pipes and equipment, despite being within the capability of the grooved coupling. The key to effectively accommodating movement in a building is to allow controlled movement and that can be done with grooved technology.

As a reminder, there are two basic grooved coupling styles:

- Flexible grooved couplings – These allow a limited amount of angular movement.

- Rigid grooved couplings – These do not allow movement and can be used wherever immobility in the pipe joint is needed, similar to a flanged or welded joint.

The Test

Victaulic couplings were tested at the ATLSS center, a member of the nationally recognized NEES (Network for Earthquake Engineering Simulations) testing group, to prove the durability of Victaulic grooved system components when exposed to seismic movements. Victaulic couplings ranging in size from 4″-16″ (100mm – 400mm) were exposed to accelerations up to 50% greater than the Northridge, California earthquake. http://www.nees.lehigh.edu/

The Result

The water-filled assemblies were pressurized to 200psi/1375 kPa for the duration of each test and no pressure loss or leakage was noted during any of the tests.

Featured Case Studies

The Petronas Twin Towers are the second tallest buildings in the world. The building needed to accommodate structure shrinkage and structure movement/sway due to wind load in risers. This required an innovative piping solution.

.

There are 4 advantages of using Victaulic couplings to accommodate pipe movement due to thermal changes

Pipe design flexibility

Reduced stress on the piping system

A more compact, inspectable and productive method of installation over other pipe-joining methods such as welding

Conforms to industry practices in industrial building services

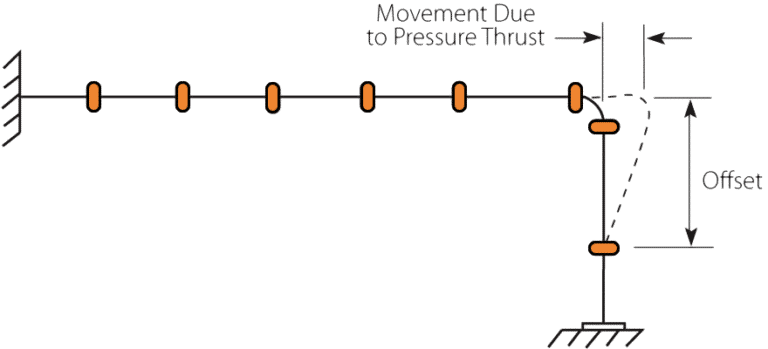

The key to effectively accommodating pipe thermal expansion and contraction in a building is to allow the predictable, controlled movement of the piping itself. This can be achieved in a variety of ways; the selection of a specific method is based upon the engineer, the type of piping system and the project parameters.

expansion

Contraction

4 ways grooved couplings accommodate thermal movement

- they provide an expansion joint utilizing grooved mechanical pipe components

- they allow the system to “free-float”

- they utilize the linear movement/deflection capabilities of flexible grooved couplings

- they provide an expansion loop utilizing grooved mechanical components

3 reasons why grooved couplings are a smart alternative

- Grooved pipe couplings are easier and faster to install over welding

- They accommodate movement within the design capability of the grooved coupling, and are done within the product’s “free range of motion.”

- Piping system movement caused by pipe thermal expansion and contraction can be accommodated in smaller spaces, with low stress on the components.

Noise and Vibration Attenuation

it can be done with grooved technology and here is how and why you want to use it.

Mechanical room equipment creates noise and vibration in a piping system, which can be difficult to contain. Designers can specify the use of Victaulic couplings to isolate this vibration.

In addition, Victaulic flexible couplings will also accommodate for misalignment, reduce stress on pumps and equipment connections, and accommodate linear movement and angular deflection in a piping system.

How do Victaulic couplings dampen noise and vibration?

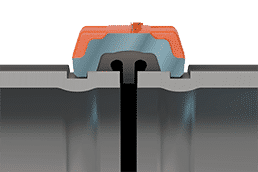

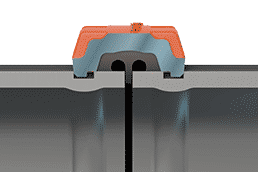

The unique construction of our grooved coupling enables the gasket to seal against pipe, while the housing provides both space for the seal to flex and containment to prevent overstretching. Our couplings work to create a permanent leak-tight seal, with no need for additional reinforcement. Additionally, ductile iron also absorbs sound.

As a reminder, there are two basic grooved coupling styles:

- Flexible grooved couplings – These allow a limited amount of angular movement.

- Rigid grooved couplings – These do not allow movement and can be used wherever immobility in the pipe joint is needed, similar to a flanged or welded joint.

Is there proof Victaulic grooved couplings reduce pipe vibration?

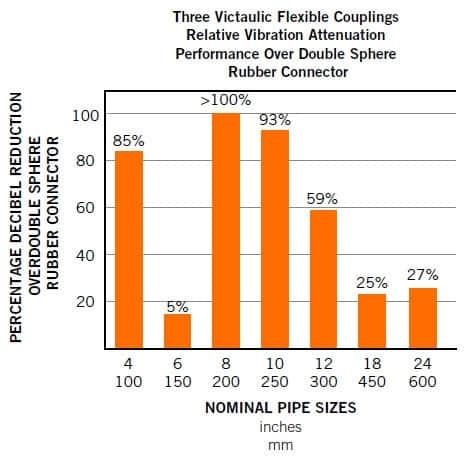

Yes. In 2013, Victaulic completed testing at NASA’s Vibration and Acoustic Test Facility (VATF). The results showed that the vibration attenuation provided by three (3) Victaulic flexible couplings, installed near the source of vibration, outperformed the double sphere rubber connectors and stainless steel braided pump connectors.